Located in the heartland of America, Cast Technologies proudly offers premier generator set casting services in Illinois. With a legacy of precision engineering and craftsmanship, our foundry specializes in delivering durable and high-quality castings tailored to meet diverse industrial needs. Leveraging state-of-the-art technology and experienced metal foundry workers, we ensure that each cast component exceeds industry standards. Whether for backup power solutions or large-scale industrial applications, our comprehensive casting services in Illinois are committed to delivering innovative, reliable, and cost-effective solutions that power your success.

Generator set castings play a pivotal role in ensuring reliable energy solutions across various industries. High-quality castings are essential to the performance and longevity of generators. By utilizing advanced materials such as aluminum, steel, and iron, Illinois foundries can craft robust components that withstand rigorous operational demands. As a casting company rooted in tradition and innovation, we understand the intricate balance between quality and efficiency. Our services encompass the entire casting process, ensuring that every product meets the highest standards. This focus on quality and materials underscores the critical nature of casting in powering efficient generator systems.

Quality is paramount when it comes to generator set castings. Generators are often the heartbeat of operations, crucial in providing uninterrupted power supply during outages. High-quality castings ensure that these systems operate smoothly without fail. The integrity of the casting process directly affects the performance and reliability of the generator. Any defects or inconsistencies in the castings can lead to potential malfunctions or downtime, which, in industrial settings, can be costly both financially and operationally. This is where attention to quality is vital. In Illinois, foundry operations focus on achieving precision through techniques such as high-quality die casting. This process utilizes molds to produce consistent and durable components, ensuring each piece is ready to meet the toughest challenges. The choice of casting company also plays a substantial role.

At Cast Technologies, our deep understanding of materials not only supports high performance but also extends the life of generator systems, thus safeguarding investments. Utilizing industry-leading practices and insights, Illinois-based castings can provide unmatched resilience and dependability. A commitment to quality, therefore, anchors the whole casting system, confirming that each produced component upholds the standard of excellence required in generator applications, helping to bridge the gap between demand and seamless energy supply.

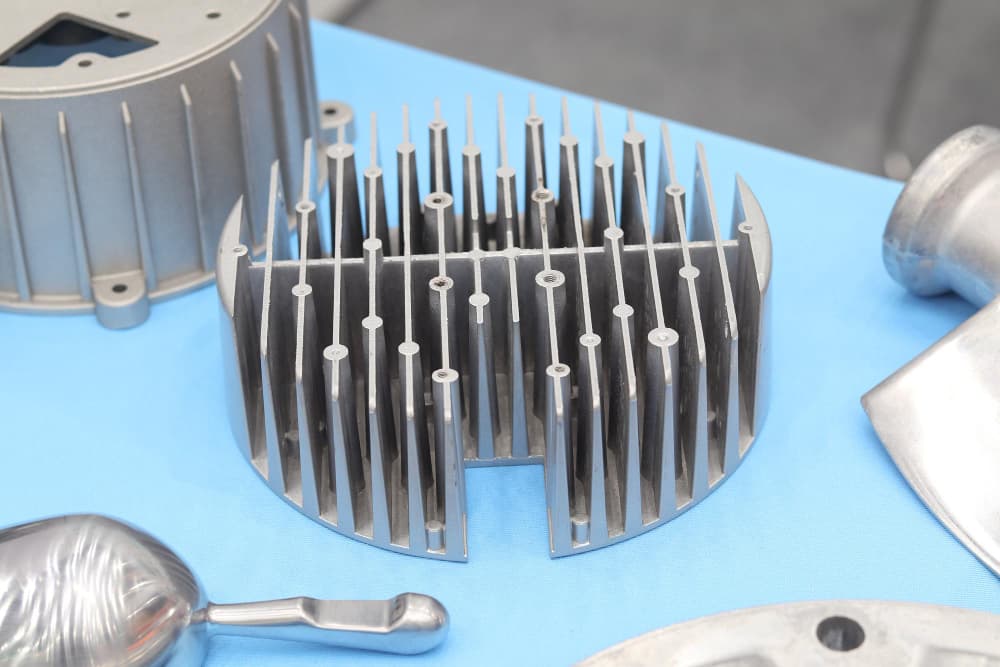

In Illinois foundries, the selection of metals is a fundamental aspect of developing effective generator castings. Metals such as aluminum, steel, and iron are chosen for their distinct properties and performance characteristics. Aluminum, known for its lightweight yet durable nature, offers excellent resistance to corrosion, a vital trait for generator components exposed to varying environmental conditions. It’s an ideal choice for high-efficiency generators, where weight reduction can lead to enhanced performance. Steel, on the other hand, is lauded for its strength and toughness. Foundries often employ steel in the casting process when the situation demands robustness against mechanical stress. This makes it suitable for heavy-duty generators used in industrial settings. Iron remains a classic choice, valued for its unparalleled ability to absorb vibrations, reducing noise and enhancing durability in structural parts. The selection process isn’t just about the metal itself, but also about the foundry’s capability to work with these materials to produce superior castings. At Cast Technologies, our expertise in casting services means we can adapt to diverse requirements, delivering high-performing components tailored to specific generator needs. Through continuous advancements and technological integration, Illinois casting companies maintain an edge in utilizing these metals, ensuring that the final product not only meets but exceeds market expectations, embodying the strength and reliability that customers trust.

Illinois stands as a beacon in the world of casting services, thanks to its robust foundry industry that anchors local and national markets. This state’s foundries specialize in producing high-quality aluminum die castings, which are vital for industries relying on durable and efficient machinery. With a focus on precision, Illinois foundry services ensure components meet the rigorous demands of modern technology. These foundries don’t just cast metal; they shape the future with advancements in die cast technology. Emphasizing reliability and innovation, they offer a wide range of solutions that cater to various industrial needs, underscoring their pivotal role in the sector.

In Illinois, casting companies have positioned themselves as leaders by leveraging their expertise in aluminum die casting. These casting companies are not merely fabricators of metal but innovators who push the envelope in casting technology. An aluminum foundry in this region excels at producing metal components that are not only lightweight but also durable and cost-effective. Aluminum, known for its excellent heat dissipation and resistance to corrosion, is a prime material for creating components that are both robust and efficient. Industries ranging from automotive to aerospace rely heavily on aluminum castings for their operational equipment, attributing their performance and efficiency to the high-quality castings produced by these foundries. Beyond traditional casting, these companies are integrating cutting-edge technology to streamline processes and enhance quality. Innovations such as vacuum die casting and pressure die casting allow for greater precision and consistency across produced components. This technological edge translates into castings that meet the exact specifications required by modern applications. Furthermore, partnerships with suppliers extend the capabilities of these casting companies. By collaborating with industry leaders in raw material supply, Illinois foundries can maintain quality control across their operations, thus ensuring the reliability of the components they produce. Every aluminum die casting company in Illinois is committed to sustainability as well. By adopting eco-friendly practices and refining their processes, these companies are reducing their carbon footprint while maintaining production efficiency. The dedication to quality, technology, and environmental responsibility makes Illinois’ casting companies a vital part of the state’s industrial ecosystem, supporting sectors that rely on dependable casting solutions.

Technological advancements have substantially transformed the landscape of die cast technology in Illinois’ foundry services. With an eye on precision and efficiency, casting companies are continually innovating to enhance the quality and performance of their castings. One of the pivotal advancements has been the integration of computer-aided design (CAD) systems. CAD technology allows foundries to design complex geometries with unprecedented accuracy, significantly improving the prototyping and production phases. This advancement ensures that each casting meets stringent quality standards while reducing waste and production costs. Moreover, automation is reshaping operations within casting systems. The use of automated machinery streamlines the casting process, increasing throughput and consistency. This technology enhances the reproducibility of high-quality castings across production runs, ultimately providing better service to clients. Automated processes minimize human error and enable foundry workers to focus on quality control and innovation. Illinois foundries are also adopting advanced simulation software to predict casting outcomes accurately. These systems simulate how different metals will flow and solidify in mold conditions, allowing foundries to preemptively address potential defects and optimize the casting process for better results. Die cast technology is further augmented through continuous metallurgical research. By exploring new alloy compositions and treatment processes, foundries in Illinois stay ahead of industry demands. These advancements not only improve the durability and performance of castings but also offer tailored solutions to meet specific industrial requirements. By embracing these technological milestones, Illinois’ die casting industries can consistently deliver superior quality castings that power a myriad of applications. This forward-thinking approach, combined with an unwavering commitment to excellence, ensures that Illinois remains a leader in the foundry sector, providing reliable and innovative solutions to meet the evolving needs of modern industries.

Choosing the ideal casting company is crucial for businesses seeking high-quality generator set castings. The right partner will ensure that all components meet stringent performance standards and are crafted with meticulous attention to detail. When selecting a casting company, consider their expertise in materials like aluminum and their track record in producing precision die and sand castings. Illinois offers a wealth of experienced foundries that deliver exceptional casting services and products. This discussion examines the key factors when selecting a casting company and highlights important questions to ask potential suppliers, ensuring you make an informed decision.

When deciding on a casting company, it’s essential to assess several critical factors that can influence the quality and reliability of the final product. First and foremost, consider the company’s expertise in using materials such as aluminum, which plays a significant role in generator castings due to its lightweight yet sturdy nature. Aluminum foundries that possess advanced knowledge in die and sand casting can produce components that excel in both performance and durability. The company’s ability to provide consistent quality in their castings should be a top priority, as the integrity of generator systems heavily relies on defect-free components to avoid costly downtimes or system failures.

In addition to material expertise, the technological capabilities of a casting company cannot be overlooked. Illinois casting companies often leverage cutting-edge technologies such as computer-aided design (CAD) and automated processing to achieve precision in their products. These technological advancements ensure that each casting is manufactured to exact specifications, enhancing the overall reliability of the components. Another vital consideration is the company’s history and experience in the industry. Established companies generally have a longer track record and a broad range of industry services, which can be invaluable in solving complex casting challenges. It’s beneficial to choose a foundry that not only offers excellent products but has a proven history of innovation and problem-solving.

Furthermore, evaluating the company’s manufacturing processes is imperative. Are they transparent about their quality control measures? Do they regularly upgrade their practices to stay ahead of industry demands? Understanding their approach to sustainability and environmental responsibility can also sway the decision. Companies entrenched in eco-friendly practices showcase a commitment to both quality and community values, aligning with broader industry trends. Finally, the company’s customer service quality should not be underestimated. Professionalism, communication, and responsiveness are indicative of a foundry that values its customers and stands behind its services. Selecting a casting company involves multiple considerations, each ensuring the selected partner is capable of delivering the dependable castings essential for robust generator systems.

Navigating the process of selecting a casting company is simplified with the right set of questions that illuminate their capabilities and alignment with your needs. Initially, inquire about their experience with materials pivotal to your industry, such as aluminum, especially in the context of die and sand casting. It’s vital to understand whether they can deliver products that meet your specific requirements without compromising on quality. Ask them to provide examples of past projects similar to yours to gauge their expertise and the successful application of their skills in real-world scenarios.

Examining their technological prowess is equally essential. Ask potential casting companies about the technologies and processes they employ, like CAD or automation, and how these contribute to the precision and quality of their products. Understanding their manufacturing capabilities helps ascertain whether they can produce components consistently at scale and with the necessary precision. Their response will also reflect their commitment to staying ahead in a rapidly advancing field. Another pertinent question revolves around their quality assurance and control mechanisms. Knowing how they address quality from the onset of a project through to completion will provide insights into their level of dedication to maintaining high standards.

Service and support are crucial aspects that should not be overlooked. Query about the level of customer service you can expect and how they manage post-production support. Are they open to feedback, and do they offer solutions when issues arise? Additionally, asking how they handle potential supply chain disruptions will provide clarity about their reliability. Consider asking about their sustainable practices, too. Companies engaged with environmental responsibility often showcase a larger commitment to quality and innovation, aligning with progressive market demands. By asking these targeted questions, you’ll gain a comprehensive understanding of whether a casting company is well-suited to meet your precise industrial needs, guaranteeing that your choice in supplier not only provides essential components but also maintains a partnership that empowers your business operations.

As a leader in generator set castings, our Illinois foundry combines advanced technology with expert craftsmanship to deliver exceptional results. At Cast Technologies, we are dedicated to meeting the specific needs of our clients, providing durable and reliable casting services that ensure performance and longevity. Our commitment to quality and customer satisfaction makes us a trusted partner in the industry. Whether you require custom solutions or standard castings, we are here to help you power the future. Contact us today to discuss how we can assist with your generator set casting requirements.

Top quality casting and services via our in-house foundry & machine shop

1100 SW Washington St Peoria, IL 61602 USA

© 2023 Cast Technologies. All Rights Reserved.